Greyline Instruments AVFM 5.0 Ultrasonic Flow Meter

Displays, transmits and totalizes flow through open channels, partially filled pipes and surcharged pipes without a flume or weir.

Overview

Features

- For open channels and pipes

- No flume or weir required

- Measures velocity + level to calculate flow

- 0.1 to 20 ft/sec & reverse flow to -5 ft/sec velocity

- 1 inch to 15 feet level range

- Works in partially filled and surcharged pipes

- Measures forward and reverse flow

- 3 Isolated 4-20mA outputs (Flow, Level and Velocity)

- Totalizer and 2 control relays

- Optional intrinsically safe sensor

- Optional built-in 2-million point data logger

- Simple 5-key calibration

What's in the Box

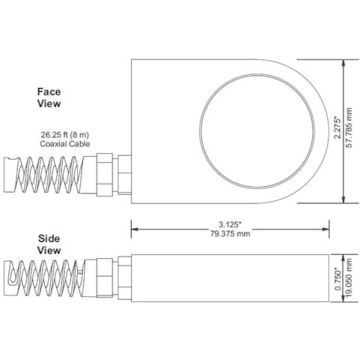

- Submersible velocity & level sensor

- Submersible, shielded 3-coaxial cable

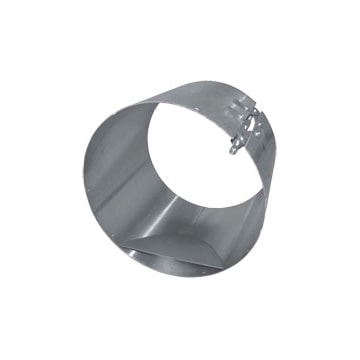

- Stainless steel sensor mounting bracket

- Installation and operation manual

Description

The Greyline Instruments AVFM 5.0 ultrasonic flow meter is designed to display, transmit and totalize flow through open channels, partially filled pipes and surcharged pipes without a flume or weir making it ideal for municipal stormwater, combined effluent, raw sewage and irrigation water applications.

The AVFM 5.0 ultrasonic flow meter measures both level and velocity to calculate flow in an open channel or pipe. The meter can measure forward flow velocity up to 20 ft/sec (6 m/sec) and reverse flow up to 5 ft/sec (1.5 m/sec). The electronics and software sample and average flow rates continuously to provide stable readings. The submerged velocity/level sensor is suitable in pipes with pressure up to 10 psi. No special set-up or adjustment is required. Minimum recommended pipe diameter is 6" (150 mm).

Setting up and using the AVFM 5.0 is simple. The ultrasonic sensor mounts inside the pipe or on the bottom of a channel with a stainless steel mounting bracket and a single screw into the bottom of the pipe or channel. No special compounds, tools or hardware are required. The sensor is completely sealed with no orifices or ports. Careful selection of sensor mounting location results in best performance and maintenance-free operation. Locations where sediment builds up should be avoided. Best possible accuracy will result when the water is not highly turbulent and where velocity is evenly distributed across the channel. The channel should not have drops or direction changes immediately upstream of the sensor mounting location. Pipe or channel slope should not exceed 3%.

The flowrate and total flow can be viewed on the AVFM 5.0's large backlit LCD display. The unit can be connected to external devices with three 4-20mA outputs and two control relays. Choose the built-in data logger option if you want the AVFM 5.0 to store time and date stamped flow values at 10 second to 60 minute intervals. Daily flow reports are automatically created. Windows software is included to display log files in graph and table formats, change measurement units and generate flow reports.

Calibration is as simple as entering the pipe diameter or channel dimensions and letting the AVFM 5.0 automatically compute and display flow volume.

Documents

Spec Sheets

Manuals

Application Notes and White Papers

Other

Links

Accessories

Cables

Sensors/Probes

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Measuring the Volumetric Flow in Large, Partially-filled Pipes

The Background: A wastewater treatment plant requires volumetric flow records of all incoming and outgoing water, treated or otherwise.

The Problem: The influent is directed from a 72-inch sewer main which is typically just 5 to 15% filled so as not to cause restrictions which could back-up the entire sewer system upstream. The challenge, then, is measuring the flow in this large, partially filled pipe.

The Solution: The Greyline AVFM ultrasonic flow meter can calculate flow in an open channel or pipe making it a great solution that is simple and easy to install. Simply program in the pipe’s geometry and a level sensor measures the fluid depth while an angled Doppler ultrasonic sensor measures fluid velocity. These two values allow the meter to calculate the cross-sectional area that the water is occupying and the volumetric flow.

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET