Dynasonics TFX Ultra Ultrasonic Flow Meter

Clamp-on ultrasonic flow and energy meters for liquids.

Overview

Features

- Measures clean liquids and those with small amounts of suspended solids or aeration

- Bi-directional flow measurement system

- Totalizer with remote reset

- Modbus RTU over RS485 communications

- Ethernet connection includes BACNet/IP, EtherNet/IPTM and Modbus TCP/IP protocols

- Large, easy-to-read digital display

- Rugged, aluminum enclosure for harsh environments

- Certified for hazardous area installation in North America and Europe

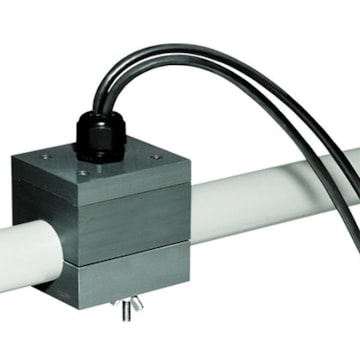

- Clamp-on sensor design for reduced installation time

- No moving parts reduces maintenance

- 4-20mA output

- 0-1,000Hz rate pulse and dual alarm outputs (flow meter model only)

- USB programming port

- RS485 Modbus network connection

Description

The Dynasonics TFX Ultra Ultrasonic Flow Meter is a clamp-on ultrasonic flow and energy meter that provides accurate and repeatable measurements for full pipe liquid applications such as cooling lines, raw sewage flows, water distribution and processes where system shutdown is impossible. This versatile and accurate meter clamps on to the outside of pipes and does not contact the internal liquid which reduces installation and maintenance time and cost. The TFX Ultra is available in a variety of configurations that permit the user to select a meter with features suitable to meet particular application requirements.

The Dynasonics TFX Ultra is available in two versions: a stand-alone flow meter, and an energy flow meter used in conjunction with dual clamp-on RTDs. The energy flow meter measures energy usage in BTU, MBTU, MMBTU, Tons, kJ, kW, MW and is ideal for retrofit, hydronic and other HVAC applications.

The TFX Ultra has a wide, bi-directional measuring range that ensures reliable readings even at very low and high flow rates. For pipe/tubing sizes of 2" and lower, the TFX Ultra includes clamp-on transducers mounted and wired directly to the flow meter electronics enclosure. This design provides a convenient installation in areas where the user requires local indication. The TFX Ultra is also available with remote mounted transducers that permit separation of up to 990ft (300m). This design is utilized when pipes are located in areas that are not convenient for viewing, or on piping systems with severe vibration.

The TFX Ultra features a rugged, compact aluminum enclosure, easy-to-read digital display, bi-directional flow measurement, and a totalizer featuring forward, reverse and net total, and Modbus communications. The TFX Ultra offers an optional Ethernet connection as well as a USB programming port. With ease of operation a key component in designing the Series TFX Ultra, Windows based software utility UltraLink is available and compatible with all Dynasonics transit time flow meters to allow users to easily configure, calibrate, and troubleshoot with a notebook PC.

Dynasonics TFX Ultra Ultrasonic Flow and Energy Meter Specifications:

| Parameter | Details |

|---|---|

| Liquid Types | Clean liquids or those containing small amounts of suspended solids or gas bubbles |

| Velocity Range | Bi-directional to greater than 40 FPS |

| Flow Accuracy | Up to 1% of reading depending upon transducer and flow rate |

| Temperature Accuracy | Option A: 32 to 122°F; Absolute: 0.22°F; Difference: 0.09°F |

| Option B: 32 to 212ºF; Absolute: 0.45ºF, Difference: 0.18°F | |

| Option C: -40 to 350ºF; Absolute: 1.1ºF, Difference: 0.45ºF | |

| Option D: -4 to 85ºF; Absolute: 0.22ºF, Difference: 0.09ºF | |

| Flow Sensitivity | 0.001 FPS |

| Temperature Sensitivity | Option A: 0.03ºF |

| Option B: 0.05ºF | |

| Option C: 0.1ºF | |

| Option D: 0.03°F | |

| Repeatability | 0.5% of reading |

| Compliance | General Safety (all models): UL 61010-1, CSA C22.2 No. 61010-1; (power options A and D only) EN 61010-1 |

| Hazardous Location (power supply options A and D only): Class I Division 2 Groups C, D; Class II and III, Division 2, Groups C, D, F, and G for US/CAN; ATEX II 2 G Ex nA II T4: UL 1604, CSA 22.2 No. 213, EN 60079-0 and EN 60079-15 CE: EN61326-1:2006 on meter systems with integral flow transducers, transducers constructed with twinaxial cable (all transducers with cables 100ft (30m) and shorter) or remote transducers with conduit | |

| Display | Two line LCD, LED backlit |

| Enclosure | Type 4 (IP65) Construction: powder-coated aluminum, polycarbonate, stainless steel, polyurethane, nickel-plated steel mounting brackets |

| Configuration | Via optional keypad or PC running ULTRALINK software |

| Engineering Units | Flow Meter and Energy Meter: Feet, gallons, cubic feet, million gallons, barrels (liquid and oil), acre-feet, lbs, meters, cubic meters, liters, million liters, kg |

| Energy Meter only: BTU, MBTU, MMBTU, Tons, kJ, kW, MW | |

| Inputs/Outputs | USB 2.0, RS485, 10/100 Base-T, 4-20mA, |

| 0-1,000 Hz: open-collector (flow meter only), Two Alarm Outputs (flow meter only) |

Documents

Accessories

Required Components

These additional components are required for the operation of your product. We strongly advise you to purchase these components unless you already own them or own a suitable alternative.

Cables

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Retro Fit Building Efficiency Monitoring

The Background: Our customer is a bottling plant looking for a way to track the amount of energy used in their hydronic heating and cooling systems.

The Problem: The building and systems are old and the customers wants a non-invasive flow meter with the ability to take in temperature inputs that can then calculate energy usage, also known as BTU monitoring without a costly shut-down of the production line. This provides a way to monitor efficiency and determine if any of the loops are running below a threshold and need to be replaced.

The Solution: We recommended the Dynasonics TFX Ultra Ultrasonic Flow Meter, a clamp-on meter that measures both flow and energy. This solution allows the customer to maintain full operation of the system while they study it’s heating and cooling efficiency.

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET