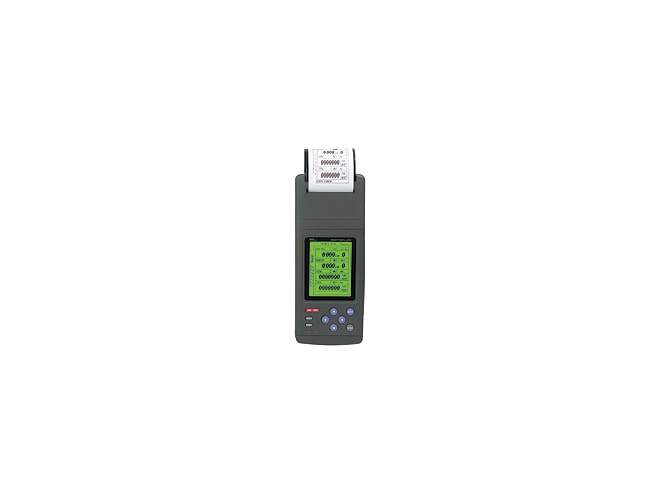

Fuji Electric Portaflow X Ultrasonic Flow Meter

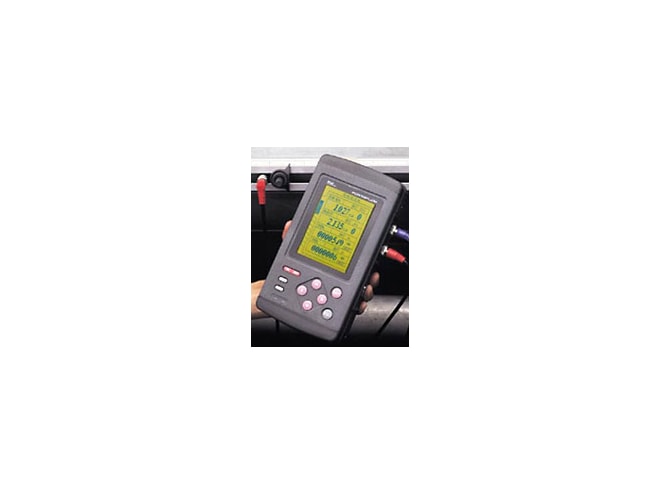

Transit time meter measures flow rates through pipes from the outside.

- FLCS1

Overview

Features

- Large backlit LCD displays flow rates and totalizing functions together

- Simple 10 min setup and easy operation

- Sound velocity measuring function eliminates temperature and pressure errors, and enables easy setup for unknown materials

- Enhanced anti-bubble measurement technology

- Compact and light-weight at 3.3 lbs

- Built-in data logger with direct download to PC

- Typical accuracy is ±0.5% to ±1.0% of velocity on calibrated system

- Variety of detectors for pipes ranging from 0.50" to 235" diameter

Description

See accessories tab.

The Fuji Portaflow X ultrasonic flow meter utilizes the transit time difference principle for measuring flow rates through pipes from the outside. The Fuji Portaflow X ultrasonic flow meter is compact, portable, and lightweight, incorporating the latest breakthroughs in digital signal processing and electronics. In addition, the Fuji Portaflow X ultrasonic flow meter realizes high performance and easy operation.

One of the most attractive features of the Fuji Portaflow X ultrasonic flow meter is the non-invasive setup, which enables multiple flow measurements of different running systems and offers a significant cost advantage over time.

Some of the most common applications of the Fuji Portaflow X ultrasonic flow meter include: backup for an already installed flow meter system, water supply and sewage treatment, flow measurement systems, boilerwater / feedwater supplies, cooling water, cooling oil, and deionized water for semiconductor manufacturing, among others. The Fuji Portaflow X ultrasonic flow meter may be set up with a wide variety of sensors from small diameters to large diameters, over a wide temperature range.

Transit Time Ultrasonic Flow Meters – Technology Explained

Transit Time ultrasonic flow meters are well-suited for relatively clean fluids with low to moderate aeration. These meters operate by comparing the time for an ultrasonic signal to travel with the flow (downstream) against the time for an ultrasonic signal to travel against the flow (upstream). The difference between these transit times is proportional to the flow, and the flow meter converts this information to flow rate and total. With this technology, the transducers are mounted on the outside of the pipe, providing tremendous advantages over more traditional and invasive flow measurement instruments such as magmeters, vortex meters, and turbine flow meters. These benefits include no system downtime for installation, no system contamination, no pressure drop, no moving parts, and no risk of leaks. This product is virtually maintenance free.

Documents

Accessories

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET