Fluke Ti20 Thermal Imager

Brings the powerful diagnostic capabilities of infrared thermal imaging to a wider range of industrial applications.

Overview

Features

- Resolution: 128 x 96

- Temperature range: -10 to 350°C

- Field of view: 20° horizontal x 15° vertical

- Accuracy: ±2°C or 2%

- Spectral response: 7.5 to 14 microns

- Manual focus

- Large, 3" color LCD display

- Laser pointer

- Internal flash storage holds 50 images

Description

The Fluke Ti20 thermal imager brings the powerful diagnostic capabilities of infrared thermal imaging technology to a wider range of industrial applications. The Fluke Ti20 thermal imager is a complete thermal imaging solution offering lowest cost of ownership of other thermal imaging systems.

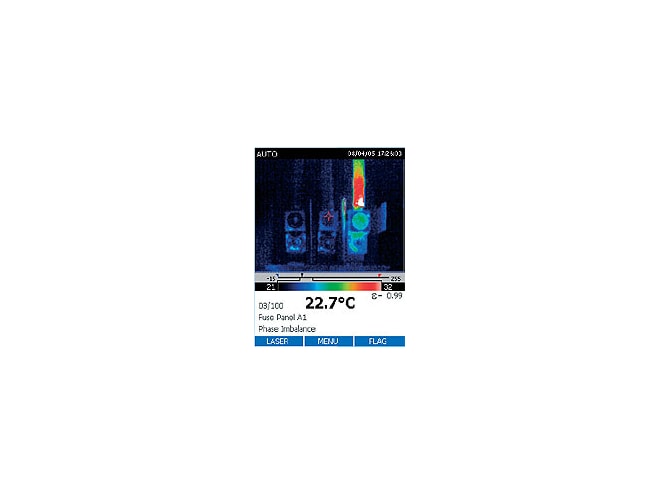

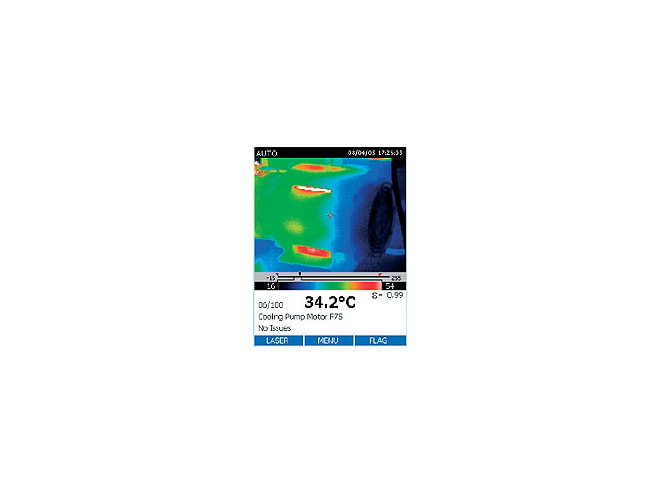

The Fluke Ti20 thermal imager is a high performance instrument designed for industrial use. Protected against dust and moisture (IP54 rated), the Fluke Ti20 thermal imager features a 128 x 96 detector that provides a clear thermal image with accurate temperature measurements up to 350°C (662°F). The Fluke Ti20 thermal imager's large color LCD displays a crisp, uncluttered image with data and step-by-step routing instructions. The Fluke Ti20 Thermal Imager is fully radiometric for detailed temperature analysis and tracking of critical components.

InsideIR™ software is included with the Fluke Ti20 thermal imager, facilitating the setup of an inspection route using unique location names, measurement setup data, and high/low temperature alarms. These routes can be uploaded to the Fluke Ti20 thermal imager for use as a routing guide.

The Fluke Ti20 thermal imager comes complete with all necessary accessories and professional application training material to ensure a fast return on investment including: InsideIR Software, a USB communication cable, an AC power adapter, two rechargeable battery packs, one AA battery case, both a hard case and a soft case, a wrist strap, and instructional materials.

Typical Applications for the Fluke Ti20 Thermal Imager

- Industrial maintenance – Check whether repairs have been performed successfully

- Predictive maintenance – Identify electrical and mechanical problems before they cause failure

- Process monitoring – Real-time observation to ensure efficient and safe operation

Documents

Accessories

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET