Site Visit to Vermont Malthouse at the Earthkeep Farmcommon

With pandemic-induced travel restrictions easing, we’ve finally been able to resume some site visits for the first time in two years. Although site visits aren’t necessarily a big part of our business, our engineers enjoy getting out to visit customers, see how we can help them, and check out some of the interesting applications our customers are involved with.

Learn About Vermont Malthouse

Recently, Matt and MaryKate visited Earthkeep Farmcommon, a collaborative farm modeling a new approach designed to improve the sustainability and environmental impact of small farms. Located just down the road from us on a historic Vermont farm, Earthkeep Farmcommon hosts around ten producers of high-quality agricultural products, much like an industrial park centered around farming.

One of those producers is Vermont Malthouse which produces and sells locally sourced grain-based pilsner and pale malt to breweries and distillers of distinction. Rob and Jamie, the Malthouse Manager and Head Maltster respectively, wanted to discuss humidity, temperature, CO2, and water submetering; all critical parameters for their operation.

The Malthouse began operations in 2020 and is in the process of retooling its malting equipment to new and updated standards, with plans to expand capacity and enable a wider range of malt offerings.

The facility is a very large concrete bunker with 3'x3' air ducts. They use the ducts and space to trick the grains into germination, essentially soaking the grain, providing a humid and hot environment, and then rapidly drying to stop the process at the exact moment to optimize the sugars in the grain to levels ideal for use in beer and spirits.

Solutions for High Temperature, High Humidity Applications

The conversation with Rob and Jamie centered around problems they were having with humidity measurement since high temperatures, high humidity applications such as theirs (160-240°F and 100% RH) are notoriously difficult due to the amount of water vapor supported by high temperatures and the amount of condensation, as liquid water is problematic in humidity measurement. While the application is tough, it’s not impossible.

Matt and MaryKate quickly determined that their existing humidity meter was right for the job but was not properly configured so they discussed the necessary changes to the meter, how to choose locations for the sensors, and how to pull the necessary temperature measurements from the new configuration thus saving them from having to purchasing an additional sensor. They also advised the customer on how to have the manufacturer rework the current humidity meter to better serve the needs of the application. MaryKate also discussed submetering their domestic water and will be quoting them multiple options.

We look forward to working together with Vermont Malthouse in the future (and also look forward to sampling some local beers using their malt!).

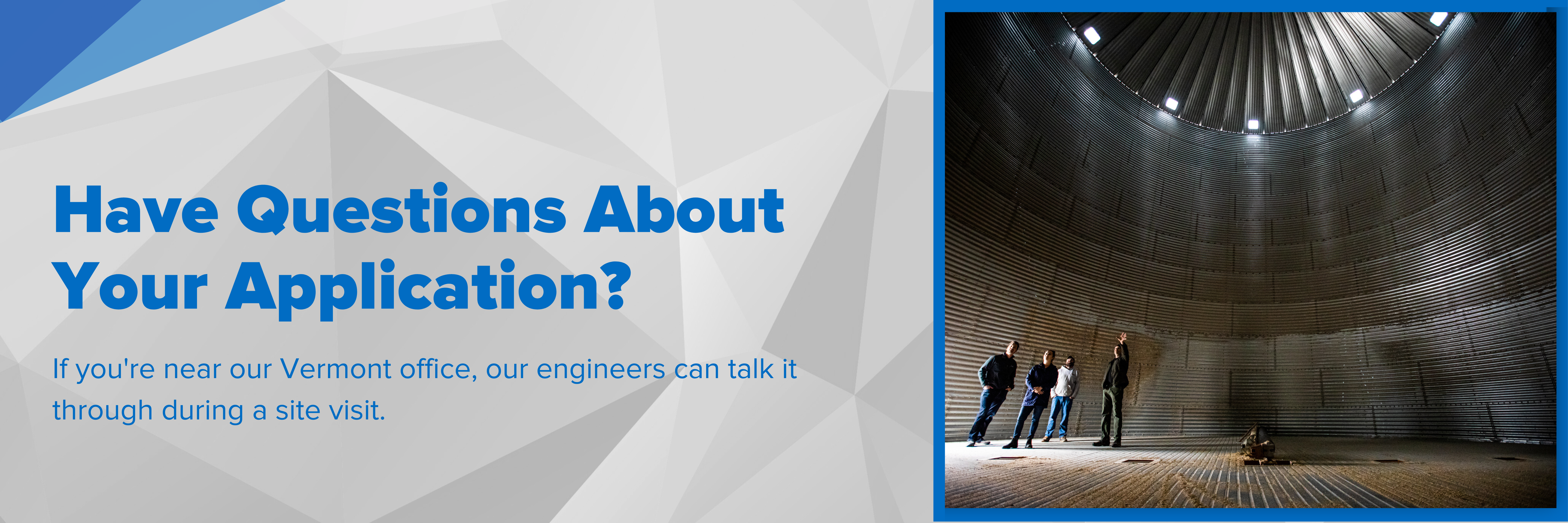

Have Questions About Your Application?

If you’re not too far from our Vermont office and have an application that’s giving you a hard time, contact our engineers and we’ll show you how our extreme customer service can get you back on track.