Keep Thermal Oxidizer Operating Costs Down by Controlling Combustible Feed Rates

The Importance of Thermal Oxidizers

Thermal Oxidizers, also known as thermal incinerators, are very important pieces of equipment for chemical plants. They control harmful emissions of volatile organic compounds, carbon monoxide, and other hazardous air pollutants. In order to do this properly, thermal oxidizers need to reach the right temperature, ensure enough time for the combustion to occur, and keep the right mixture of combustion air with the hazardous gases. If the equipment fails at any of these, the effects can be catastrophic. A fully operational and efficient thermal oxidizer helps keep a clean environment and protects inspectors from dangerous conditions.

Increase Efficiency and Keep Operating Costs in Check with an Oxygen Transmitter

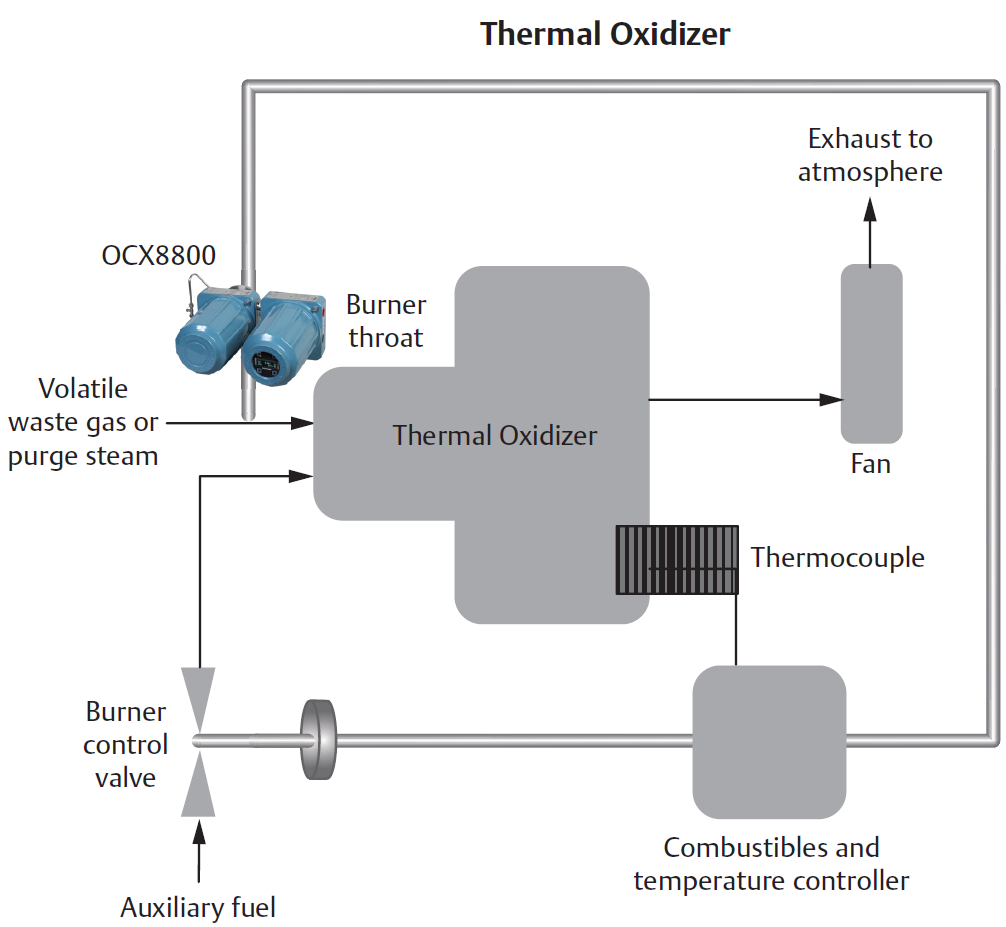

Since the feed streams don’t have enough heat on their own, an auxiliary fuel is used to complete the oxidation of the harmful compounds in the system. As mentioned above, thermal incinerators need to maintain high temperatures and the correct ratio of combustion air to hazardous gases. Chemical or combustible buildup over time can require costly and more frequent maintenance. It can also become more expensive to maintain and control the auxiliary fuel usage and combustibles content of feed streams into the thermal oxidizer.

Knowing the combustible's content makes it possible to regulate the thermal oxidizer’s auxiliary fuel firing rate which in turn reduces energy costs. Oxygen transmitters that are able to monitor carbon monoxide, hydrogen, and other hydrocarbon gases in a feed stream help to achieve this. As long as the feed gas is not ignitable, the Rosemount Analytical OCX8800 Oxygen and Combustibles Transmitter can be installed upstream of the thermal oxidizer and even operate in gases including steam purge, nitrogen purge, or combustion off-gases/air streams.

The OCX8800 Transmitter pulls a gas sample from the feed stream which is then read by a zirconia O2 sensor and calorimetric combustibles sensor. The O2 sensor is able to detect excess oxygen which helps set the combustion air supply that goes to the thermal oxidizer. The combustibles sensor detects most hydrocarbon gases up to 50,000 ppm of CO equivalent which can then help control the waste feed rate within the system as well as the firing rate necessary to oxidize the VOCs, CO, and HAPs.This combination of regulating the air supply, waste feed rate, and firing rate for the thermal oxidizer ensures that the system is operating in the most efficient way possible and reduces any excess energy usage.

Still Need Help? Call an Engineer Today

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.