Introduction to Radar Level Measurement Systems: Contacting and Non-Contacting

The efficient operation of process plants relies on accurate and reliable level measurements. These measurements are essential for optimizing process control, inventory management, and custody transfer, all of which can affect profitability. Level measurement instrumentation also plays a critical role in safety applications such as overfill prevention. Radar level measurement systems are available in contacting and non-contacting versions.

Contacting Level Transmitters:

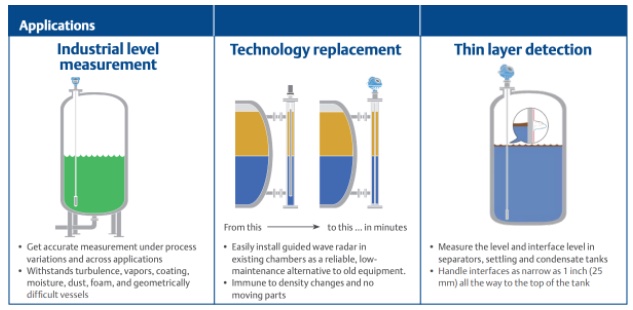

Contacting is generally a good fit for small spaces and is an easy replacement of older technology such as displacers and capacitance probes. Contacting devices, called guided-wave radar (GWR), are slightly more prevalent primarily because they are capable of providing interface level measurement (e.g. oil and water), as well as standard direct level measurements.

Guided wave radar measurement is based on the time difference between sending and receiving a microwave pulse sent down a probe and reflected back to the media surface.

- For level and interface measurement of liquids or solids

- Suitable for wide range of temperature and pressure requirements

- Top mounted

- Unaffected by media density, viscosity, conductivity, turbulence, foam, and dust

Rosemount guided wave radars are easy to install into existing tank connections and are virtually unaffected by process conditions.

- Get highly accurate and reliable direct level and interface measurements

- Solve challenges of small vessels, difficult tank geometries, and internal obstructions

- Ideal for chamber applications and for replacing older technologies

Rosemount 5300 Series Level Transmitter

- Reliably handle challenging process vessels and applications with maximum control and safety

- Tap into microwave innovations for longer-distance measurements even with lower dielectric

- Streamline configuration and diagnostics through Radar Master software, a Trex communicator, or any EDDL-based interface

Rosemount 3300 Series Level and Interface Transmitter

- Handle most liquid storage and monitoring applications with ease

- Smart, loop-powered guided wave radar technology

- High reliability and performance

Rosemount 3308 Wireless Level Transmitter

- Ideal solution for your new or remote measurements with no wiring and easy commissioning

- Built on proven technologies ensuring reliable performance and high accuracy

- Minimal maintenance and long-lasting nine-year battery life

Non-Contacting Level Transmitters:

Non-contacting is generally a better fit for dirty, viscous and/or corrosive applications and when agitators are present. Non-contacting radar transmitters perform level measurements by using frequency modulated continuous wave (FMCW) technology. Rosemount’s unique energy-efficient two-wire FMCW radar technology provides optimal performance.

A microwave signal launched into the tank is reflected back from the media surface. The level is derived from the time or frequency difference between the sending and receiving of the signal.

- For liquid or solid tank levels with wide range of temperature and pressure requirements

- Top mounted; can be isolated by valves

- Unaffected by media density, viscosity, dirty coatings, and corrosiveness

Rosemount non-contacting radar transmitters are highly accurate and reliable direct level measurement for liquids or solids.

- MultiVariable output with level, distance, volume and/or signal strength

- Immune to changing density, conductivity, temperature, pressure, viscosity and pH

- Compatible with a wide selection of materials, process connections, antenna styles and accessories

Rosemount 5408 Radar Level Transmitter

- Two-wire fast-sweep FMCW technology optimized for best sensitivity in process applications

- Available with ±0.08 in. (2 mm) standard instrument accuracy or ±0.04 in. ultra accuracy over 40 m (130 ft) measuring range

- Designed to simplify operator tasks with pictorial instructions and an intuitive software interface

- Ideal for solids applications

Still Need Help? Call an Engineer Today

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.