When Your Dew Point Measurements Matter, Choose a Chilled Mirror Hygrometer

The Basics of Chilled Mirror Hygrometers

Trace moisture is a critical factor in many processes, therefore, it needs to be monitored and controlled. There are several dew point measurement technologies such as tuned laser spectroscopy, aluminum oxide, quartz microbalance, and polymer capacitance, but the chilled mirror has the highest attainable accuracy, up to ±.1°C. They are precise and drift-free, hence used as humidity transfer standards for calibrating other instruments. Chilled mirror technology is validated by all worldwide national standards. Many of the aluminum oxide sensors and polymer capacitance sensors are calibrated using chilled mirror analyzers.

When to Choose a Chilled Mirror Hygrometer

Chilled mirror hygrometers are ideal for any laboratory or industrial application where high accuracy is paramount, typically better than 0.2°C, and where periodic re-calibration is not preferred. If precision, stability, repeatability, long life, easy maintenance, and inertness to aggressive gases are required, chilled mirror is the preferred technology.

How Does a Chilled Mirror Sensor Work?

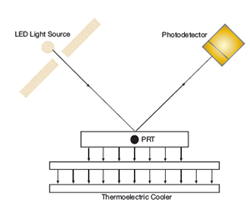

When a process gas with water vapor flows through the sensor, it encounters a tiny polished surface (mirror), typically made of copper coated with rhodium, or in the case of aggressive gases, pure platinum. Just below the mirror is a thermoelectric cooler that pumps away the heat until condensation starts to form on the mirror. The dew is detected optically by a photo emitter-detector pair. The temperature of the mirror is detected by a platinum RTD (PRT). This temperature at the moment a stable condensation or dew forms is the dew point of the gas.

Shop our selection of Chilled Mirror Hygrometers today.

The Technology Behind Chilled Mirror Hygrometers

Where does the high accuracy come from?

The optical detection of the dew is done with the help of two drift-free infrared emitter-detector pairs. The pair that detects the dew is continuously comparing with the reference pair. When dew forms initially, some of the light is dispersed. At this point, the detector signals the controller to stop cooling the mirror further. This causes the mirror to warm and the condensate to dissipate, at which point the controller starts cooling the mirror again. This heating and cooling cycle continues until there is an equilibrium between the condensate and the vapor and the dew is stable. The temperature at this point is detected very accurately by a 4-wire PRT embedded (not exposed to gases) in the copper block (excellent thermal conductor) on which the mirror is mounted. Since the fundamental dew point measurement is made by a PRT that is traceable to national standards, it makes this technology highly accurate. In addition, PRTs are known for their stability and lack of hysteresis, thus avoiding degradation in system accuracy over time.

Advantages compared to other technologies

Chilled mirror hygrometers have the widest measurement range of all technologies: 0.1ppm to 100,000 ppm, with some models sensitive to less than 5ppb moisture. Dew point measurement ranges from -100°C to +120°C. Unlike aluminum oxide and capacitance sensors, this is not affected by exposure to condensation, exposure to certain chemicals, aging, etc.

Knowing two other fundamental parameters, temperature and pressure, all other psychrometric parameters can be calculated precisely.

Chilled mirror hygrometers also have a self-cleaning feature making them very easy to maintain and frequent recalibration is not required. Mirrors can be replaced in the field.

There are also some disadvantages to chilled mirror hygrometers. Most chilled mirrors are more expensive than other moisture and dew point measurement technologies and have high power consumption compared to capacitance and aluminum oxide analyzers. Chilled mirror hygrometers are also bulkier than other analyzers which do not lend themselves easily to being deployed at multiple points along process lines and they cannot be used under high pressures.

Chilled mirror hygrometers are the most accurate method of determining the dew point or frost point of a gas containing water vapor and, by extension, analyzing trace moisture. Though your needs and budget may point you to a different type of sensor, when you need the best, only a chilled mirror will do.

Shop our selection of Chilled Mirror Hygrometers today.

Still Need Help? Call an Engineer Today

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.