Watlow Flange Immersion Heater

Flanged immersion heaters for heating liquids and gases in tanks and pressure vessels.

- IMMERSION-FLANGE

- By Watlow

- Made in the USA

Overview

Features

- ANSI/ANSI compatible 3 to 14 inch flanges available

- Flange sizes up to 24 inches available on made-to-order units

- Element sheath and flange materials to meet application needs

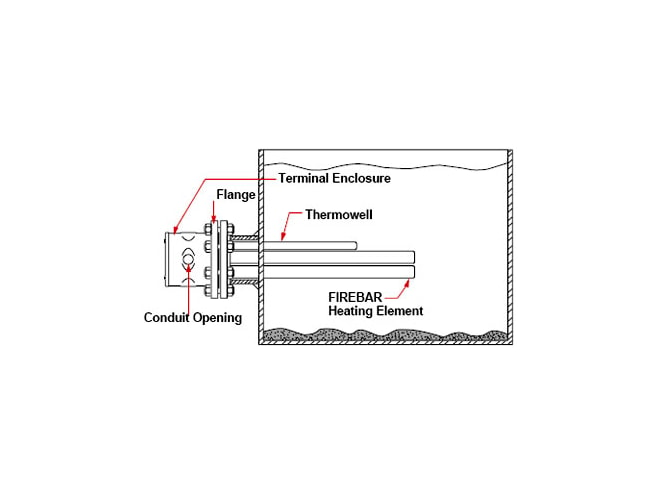

- Integral thermowells provide temperature sensor insertion and replacement without draining fluid being heated

- Standard, general purpose (NEMA 1) terminal enclosure for easy access to wiring

- All units are inspected and/or tested for seal leakage

Description

Watlow flange immersion heaters are easy to install and maintain. Designed for heating liquids and gases in tanks and pressure vessels, Watlow flange immersion heaters are ideal for applications requiring higher kilowatts.

Watlow flange immersion heaters feature Watlow's industry leading WATROD® or FIREBAR® heating elements. These elements can be brazed, staked, or welded to a four- or six-bolt flange and mounted directly to a mating flange that is welded to a tank wall nozzle.

Watlow flange immersion heaters, with FIREBAR® elements, also answer the need for liquid immersion applications requiring high kilowatts in small tanks. The FIREBAR® element's unique flat surface geometry packs more power in a smaller bundle, with lower watt density, making it especially well suited for petroleum-based liquid heating applications.

By using WATROD® or FIREBAR® heating elements, Watlow flange immersion heaters are rated up to one megawatt and can generate watt densities up to 100 W/in2 and sheath temperatures up to 1600°F (depending upon sheath material).

Watlow flange immersion heaters are available with a wide array of options to tailor each heater to your particular application. To provide process temperature control, Watlow offers optional single pole, single throw (SPST) and double pole, single throw (DPST) thermostats. Additionally, there are a number of terminal enclosures available to protect wiring from moisture, corrosion or to provide an air-insulating barrier between the flange and terminal enclosure. Type J or K thermocouples, which offer more accurate sensing of process and/or sheath temperatures, may be inserted into the thermowell or attached to the heater's sheath. For forced circulation applications, baffles can be arranged on the heating element bundle to enhance and/or modify fluid or gas flow for better heat transfer. A number of material and size options are also available.

Applications for the Watlow Flange Immersion Heater

- Industrial water rinse tanks

- Hydraulic oil, crude, asphalt

- Lubricating oils at API specified watt densities

- Vapor Degreasers

- Paraffin

- Caustic Solutions

- Air and gas flow

- Chemical Baths

How to order

Please contact us to order a Watlow flange immersion heater. To help us determine which Watlow flange immersion heater will best satisfy your application requirements, please determine as closely as possible the required flange size and material, volts, watts, phase, number of circuits, number of elements, element size and termination options of the heater you will need. Please consult the Watlow Flange Immersion Heater Data Sheet PDF for additional information.

Documents

Applications

This product can be used in the following applications:

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET