Watlow FIREROD Immersion Heater

Compact, versatile immersion heater for water or water solutions 90% or above.

- FIREROD-I

- By Watlow

- Made in the USA

Overview

Features

- Maximum operating temperature in water to 100°C (212°F) at atmospheric pressure

- Maximum watt density to 300 W/in2 (46.5 W/cm2)

- Maximum voltage to 480VAC

- Incoloy sheath resists corrosion from water

- Optional stainless steel fittings are available for use in corrosive applications

Description

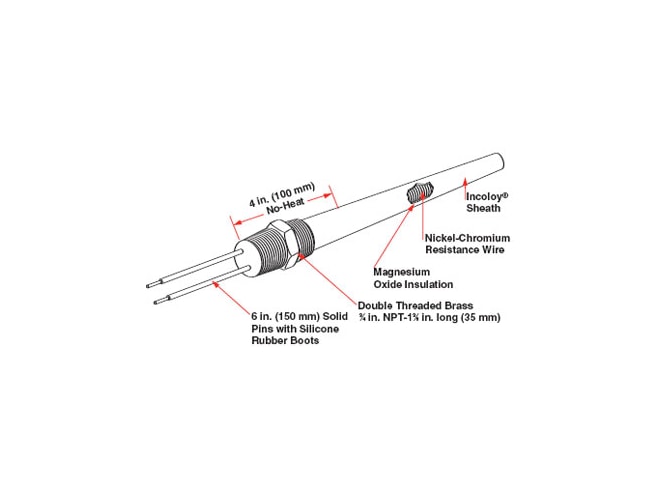

The Watlow FIREROD® heater revolutionized the heating element when it was introduced. With premium materials and tight manufacturing controls, the Watlow FIREROD® heater continues to provide superior heat transfer, uniform temperatures, and resistance to oxidation and corrosion even at high temperatures. Taking the cartridge heater one step further, the Watlow FIREROD® immersion heater packages watt densities up to 300 W/in2 (46.5 W/cm2) in a compact unit, giving you greater versatility in designing your heating system. This design solution is ideal for replacing large screw-plug immersion heaters.

The small size and big capacity of Watlow FIREROD® immersion heaters make them ideal cartridge heating units in cramped quarters. Equipped with smaller threaded fittings than conventional immersion heaters, Watlow FIREROD® immersion heaters leave room for more units in the same space. Replacement of single Watlow FIREROD® immersion heaters in multiheater assemblies is fast and easy, and avoids discarding the complete assembly.

Aside from its versatile design, the Watlow FIREROD® immersion heater comes complete with a brass 3/4 inch NPT double threaded screw plug, which allows you to add conduit boxes. Also, Watlow FIREROD® immersion heaters are sealed at the lead end with a silicone rubber seal to give protection from damp atmospheres outside the tank. Solid copper leads with silicone rubber sleeves are provided for unconfined wiring. Watlow FIREROD® immersion heaters are recommended for immersion in water or 90+ percent water soluble solutions.

When heating liquids of low viscosity, Watlow FIREROD® immersion heaters have the high watt density to pack more heat into tight spots. When heating viscous liquids, such as oils, watt densities must be kept low to prevent carbonization at the heater sheath. The Watlow FIREROD® immersion heater offers advantages for heating viscous materials where long life and high quality outweigh the usual economic considerations. As in all immersion applications, scale build-up on the sheath and sludge on the bottom of the tank must be carefully controlled to assure long heater life.

Built for sustained operation at high temperatures, the Watlow FIREROD® immersion heater is especially valuable in heat-transfer applications with liquid metals. This factor alone has made the Watlow FIREROD® immersion heater a widely used component in the development of nuclear power systems.

Applications for the Watlow FIREROD® Immersion Heater

- Plastic reclamation

- Food preparation

- Lab equipment

Ordering Information

Please contact us to order a Watlow FIREROD® immersion heater. To help us determine which Watlow heater will best satisfy your application requirements, please determine as closely as possible the overall length, immersed length, heated length, diameter, watts, voltage and threaded fitting material of the heater you will need. Please consult the Watlow FIREROD® Immersion Heater Data Sheet PDF for additional information.

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET