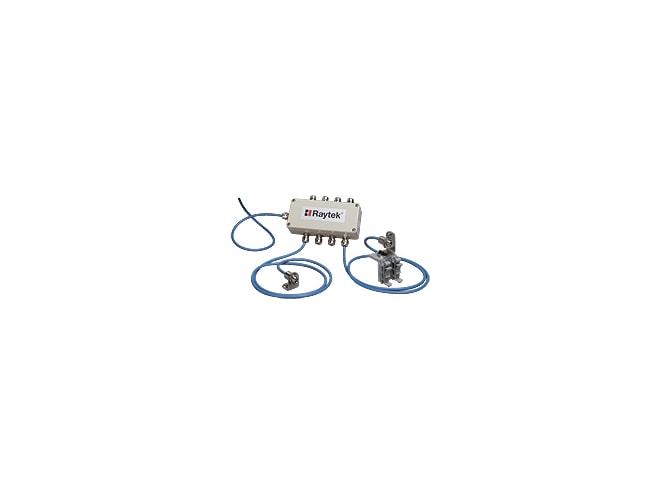

Raytek RAYEMS Equipment Monitoring System

Continuous 24/7 system monitoring, early detection of thermal issues, less waste from unexpected downtime.

Overview

Features

- Continuous 24/7 system monitoring

- Optical resolution D:S 10:1

- ±(1% of reading or 1°C) accuracy

- DataTemp multidrop Software

- IP65 (NEMA 4) rated control box and sensors

- Audible alarm for easy warning notification

- RS-485 communication for remote set up

- Operational component temperature viewed safely

- Early detection of thermal issues

- Less waste from unexpected downtime

- Maintenance performed when needed not when estimated

- Reduced maintenance cost

Description

The Raytek RAYEMS Equipment Monitoring System is an early warning device that provides live temperature data to operators, allowing them to make educated decisions regarding the functionality of their equipment. A temperature rise or spike on the surface of equipment can be a leading indicator that there may be an equipment problem. Being aware of that temperature change means system diagnostics can be done and service planned with no interruption to production - saving money in time and resources.

The Raytek Equipment Monitoring System is a non-contact infrared monitor that provides a 24/7 temperature measurement of actively powered components or operating machinery. Temperature is displayed on its LCD control module and/or remotely through PC-based Raytek DataTemp Multidrop software.

The Raytek Equipment Monitoring System is plug and play utilizing the field proven technology of the Raytek Compact Series MI3 sensor. The system is small in size to fit in tight, hard-to-reach or enclosed locations. The system monitors temperature ranges of -40˚C to 600˚C (-40˚F to 1112˚F) and all components are IP65 rated to ensure long life in harsh environments.

Users can manually program alarm settings through the integrated push button panel located on the control module or easily communicate remotely from a central location via RS-485 and DataTemp software. For full factory or machine control, an ASCII Protocol will allow the system to communicate with your own internal control network.

Documents

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET