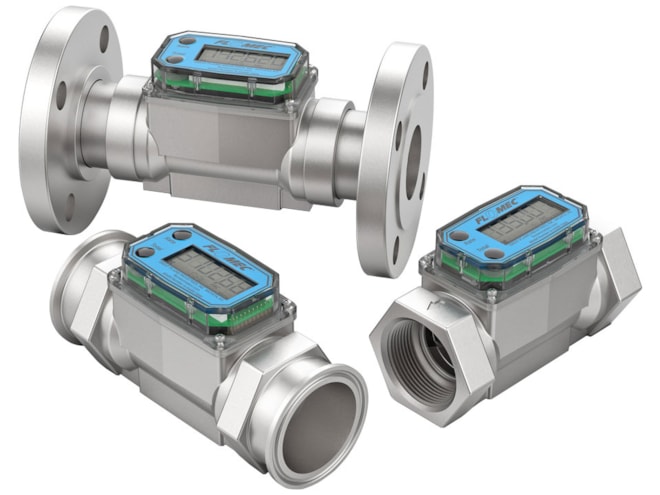

Flomec GPI G2 Turbine Flow Meter with Q9 Display

Flow range from 1 to 10 up to 20 to 200 GPM, variety of housing materials for use in water, chemical and fuel products.

Overview

Features

- Up to 200 GPM (760 LPM)

- 1/2- to 2-inch turbine sizes

- Designed for thin fluids less than 100 cp

- Modular design for use with output modules, sensors and remote transmitters

- 2 totals (1 resettable, 1 cumulative)

- Factory calibration in gallons and liters

- Two user calibrations and flowrates

- High accuracy meter

- Excellent chemical compatibility

- Internal parts are simple to replace for easy maintenance

- 2-year AAA alkaline battery life

Description

The Flomec GPI G2 turbine flow meter with Q9 display is an industrial grade meter offering durable, compact, and high-precision fluid measurement. By combining a turbine and a basic flow sensing device with a direct-mounted, microprocessor-based computer, the entire GPI G2 turbine flow meter system is incorporated into one device that is FM-approved for intrinsically safe Class 1, Division 1 uses.

The GPI G2 turbine flow meter's modular design allows for maximum flexibility. The G2 offers five turbine sizes for specific flow ranges and several standard computer configurations. The additional custom computer configurations and output options provided by GPI accessories allow the user the ability to build a metering system to meet specific and demanding needs.

The field-proven GPI G2 turbine flow meter performs impressively in fluid-handling applications such as processing, maintenance, refining, production, transportation, assembly, and service. While precise enough to meet the exacting specifications of laboratory conditions, the G2 is also rugged enough to work dependably in severe refinery environments. The G2 can be configured with high-quality aluminum, stainless steel, high pressure stainless steel, or PVDF housing to allow customization for a variety of applications. GPI G2 turbine flow meters are high accuracy, easy to use, easy to access, and easy to service.

Flomec GPI G2 Turbine Flow Meter with Q9 Display Applications

- Batching

- Food and beverage processing

- Blending

- Fuel products

- Water

- Monitoring clean fluids

- Industrial fluids

- Plant process water

- Plating solutions

- Chemical feed lines

- Ammonium

- Harsh chemicals such as sulfuric acid and bleach

Documents

Spec Sheets

- GPI G2 Turbine Flow Meter with Q9 Display - Non-Approved Datasheet (411 KB)

- GPI G2 Turbine Flow Meter with Q9 Display - Intrinsically Safe Datasheet (481 KB)

- GPI Remote 4-20mA Transmitter Datasheet (99 KB)

- GPI Q9 Computer Electronics Datasheet (731 KB)

Manuals

- GPI G2 Turbine Flow Meter with Q9 Display PVDF Approved Housing Manual (1.4 MB)

- GPI G2 Turbine Flow Meter with Q9 Display Aluminum/SS Housing Approved Manual (1.3 MB)

- GPI G2 Turbine Flow Meter with Q9 Display Aluminum/SS Housing Non-Approved Manual (1.3 MB)

- GPI G2 Turbine Flow Meter with Q9 Display PVDF Non-Approved Housing Manual (872 KB)

- GPI Q9 Computer Electronics Non-Approved Manual (3.4 MB)

- GPI Q9 Computer Electronics Approved Manual (4.8 MB)

Links

Accessories

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET