Micro Motion FDM Fork Density Meter

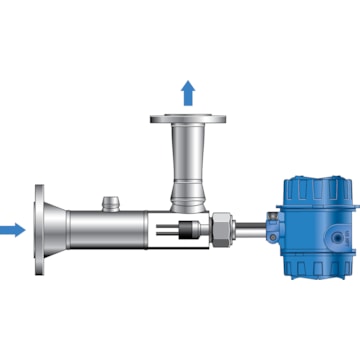

Direct-insertion meter for continuous, real-time density and concentration measurement in pipelines, bypass loops, and tanks.

- By Micro Motion

Overview

Features

- Vibrating element liquid density meter

- 0 to 3.0g/cm3 (3000kg/m3) operating density range

- ±0.001g/cm3 (±1 kg/m3) accuracy

- 100Ω RTD integral temperature sensor

- Up to 392°F (200°C) process temp

- -40 to 149°F (-40 to 65°C) ambient temp

- 95% RH, non-condensing at 140°F (60°C) humidity limit

- Conforms to EMC standards

- Certified compliant with EN 61326

Description

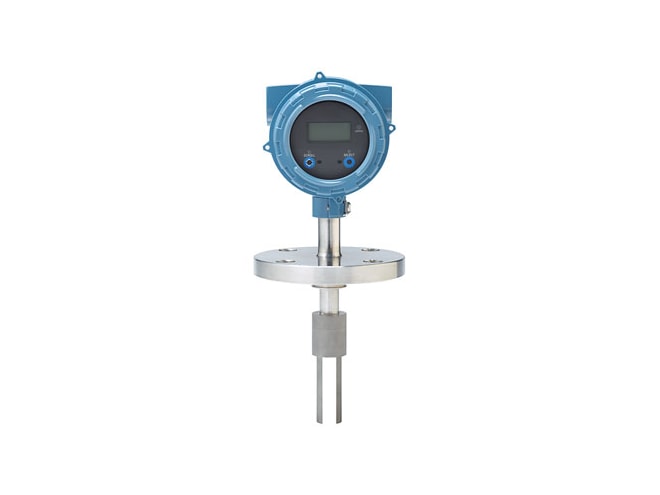

The Micro Motion FDM fork density meter has three main components, vibrating tines, piezoelectric crystals, and a temperature sensor. A head-mounted transmitter supports local configuration and optional display for multi-variable I/O, meter health, and application capabilities. The standard process measurement variables are density, temperature (also external temperature when an external device is connected), and drive gain. A range of derived output variables are also available, depending on the application configuration.

- Referred density (concentration)

- Referred density (API tables 53A, 53B)

- Specific gravity (concentration)

- %Alcohol

- Alcohol proof

- °API

- °Balling

- °Baume

- °Brix

- °Plato

- %Mass

- %Solids

- °Twaddle

- User-defined calculation output

If an external device is connected, mass flow, net solids flow, enhanced concentration accuracy, referred density (API tables with live pressure input), and tank mass can also be derived. Integral HART I/O allows direct input of external temperature, pressure, and flow measurements for enhanced measurements.

The optional local display is a segmented two-line LCD screen that can be rotated in 90-degree increments for ease of viewing, and has optical switch controls for hazardous area configuration and display. A three-color LED indicates meter and alert status. Functional benefits of the optional display include:

- View process variables

- View and acknowledge alerts

- Configure mA and RS-485 outputs

- Supports Known Density Verification (KDV)

Documents

Spec Sheets

Manuals

- Micro Motion FDM Fork Density Meter Manual PDF (3.0 MB)

- Micro Motion FDM Fork Density Meter Installation Manual PDF (3.2 MB)

- Micro Motion FDM Fork Density Meter Foundation Fieldbus Manual PDF (1.5 MB)

Application Notes and White Papers

Links

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET

Effective April 15th, 2025 Micro Motion has added a 6.7% surcharge for all of their products. The surcharge will appear as a separate line item on the order.

Effective April 15th, 2025 Micro Motion has added a 6.7% surcharge for all of their products. The surcharge will appear as a separate line item on the order.