Dwyer 2000 Series Magnehelic Pressure Gauges

Low pressure Magnehelic gauges with frictionless movement to quickly indicate positive, vacuum or differential pressures.

Overview

Features

- For use with air and compatible, non-combustible gases

- Die cast aluminum case and bezel, with acrylic cover

- Exterior finish is coated gray to withstand 168 hour salt spray corrosion test

- Pressure ranges to 30 psi (or equivalent)

- Accuracy up to ±2% of FS

- 4" diameter dial face

- Temperature limits: 20 to 140°F

- 1/8" female NPT duplicate high and low pressure taps - one pair side and one pair back

- Bezel provides flange for flush mounting in panel

- Zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover

- RoHS approved

What's in the Box

- (2) 1/8" NPT plugs for duplicate pressure taps

- (2) 1/8" pipe thread to rubber tubing adapters

- (3) Flush mounting adapters with screws

Description

The Dwyer 2000 series pressure gauge uses Dwyer's simple, frictionless Magnehelic® gauge movement, to quickly indicate low air or non-corrosive gas pressures — either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. There is no manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

The Dwyer 2000 series is available in ranges up to 30 psi (or equivalent) and is accurate up to ±2% of FS. The gauge is available in a number of pressure units, including dual scale. Compound ranges are also available. A number of options can be added to tailor the 2000 series gauge to your specifications.

The Dwyer 2000 series pressure gauge has a 4-inch dial face. It can be either flush or surface mounted with standard hardware supplied. Although calibrated for vertical position, many ranges may be used at any angle by simply rezeroing. However, for maximum accuracy, they must be calibrated in the same position in which they are used.

Dwyer Magnehelic® gauges are the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Documents

Accessories

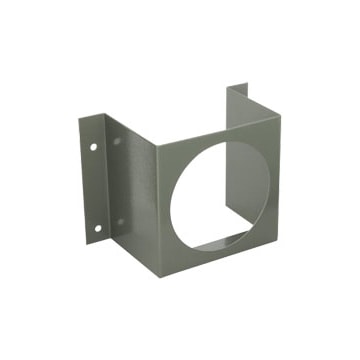

Mounting Bracket

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Monitoring Dust Filters

The Background: Our customer is a food processing company that prepares raw grains for use in some of their products. They seek a means of identifying when dust filters need to be cleaned or replaced.

The Problem: Grains create a dust hazard as they are transported through various stages of preparation. A number of dust filters are used to mitigate this hazard but those filters clog easily in the heavy dust. Clogged filters hinder the airflow throughout the facility.

The Solution: We recommended the Dwyer 2000 series pressure gauge which uses Dwyer's simple, frictionless Magnehelic gauge movement, to quickly indicate low air pressures either positive, negative (vacuum) or differential. By measuring the differential pressure across the dust filters, our customer can quickly and easily determine when the filters need to be cleaned.

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET