Greyline Instruments SLT 5.0 Level & Flow Monitor

Non-contact ultrasonic system used to measure & control liquid level or monitor & totalize open channel flow through any flume or weir.

Overview

Features

- Non-contact measurement of level or open channel flow

- ±0.25% of Range or 2mm (0.08in) accuracy

- Repeatability and Linearity: ±0.1%

- Simple 5-key calibration

- Isolated 4-20mA output

- Programmable control relays

- NEMA4X (IP66) polycarbonate enclosure

- Watertight & dust tight with shatterproof cover

- False echo rejection

- 2 programmable control relays (upgradeable to 6)

- Electrical surge protection

- Intrinsically safe sensor option

- Plug and play relay and data logger options

What's in the Box

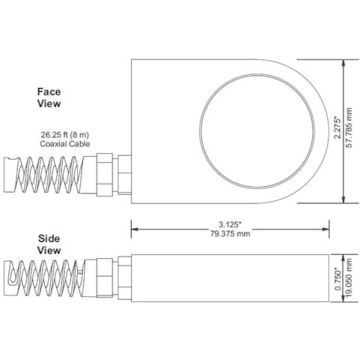

- Level sensor

- Coaxial sensor cable

- PC software utilities disk

- Installation and operation manual

- NIST certificate

Description

The Greyline Instruments SLT 5.0 level and flow monitor is a versatile instrument designed to continuously measure, display, transmit and control liquid level in storage tanks and pumping stations, or to monitor and totalize open channel flow through any flume or weir. The non-contact ultrasonic sensor mounts above the liquid being measured so it will not obstruct the flow nor be prone to fouling.

The SLT 5.0 is easy to set up and operate. Use the built-in 5-button keypad/menu system to input the calibration parameters and the SLT 5.0 will quickly calculate the volume in horizontal round tanks, or flow rate (and total) through any flume or weir. The standard PVC and Teflon sensor is rated for measurement ranges up to 32ft. The SLT 5.0 provides an accuracy up to 0.25% of Range or 2mm (0.08in) whichever is greater.

The SLT 5.0 has an isolated 4-20mA output which can transmit flow data to remote chart recorders or displays. The two control relays (upgradeable to six) are programmable for level/flow alarm, and flow proportionate pulse (for samplers, chlorinators or remote totalizers). An Intrinsic Safety Barrier is optional for sensor and cable installation in hazardous rated locations. The separate, watertight electronics/display enclosure is mounted at a convenient location within 500ft (150m) of the sensor

Documents

Spec Sheets

- Greyline Instruments SLT 5.0 Level & Flow Monitor Datasheet PDF (188 KB)

- Explosion-Proof NEMA7 Enclosure Datasheet PDF (693 KB)

Manuals

Other

Links

Accessories

Cables

Sensors/Probes

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Manhole Flow Monitoring

The Background: Our customer is a municipal utility that needs to monitor flow through an open channel accessed through a manhole.

The Problem: The flow though the channel is intermittent drainage and, as such, the application cannot insure the full pipe standard that standard inline flow meters require.

The Solution: We recommended the Greyline SLT5.0, a non-contact ultrasonic flow meter optimized for open channel flow monitoring. After installing a flume in the channel, the SLT 5.0 was used to measure the fluid level in the flume and calculate the flow rate and total flow through the channel.

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET