Dynasonics TFXL Series Ultrasonic Flow Meter

Ultrasonic flow meter for liquids with small amounts of suspended solids or aeration, replaces the YD50-C.

Overview

Features

- 11-28 VDC @ 0.25A

- 0.1 to 40 FPS (0.03 to 12 MPS)

- 4-20mA output or TTL (pulse or simulated turbine meter)

- -40 to 185°F (-40 to 85°C) ambient temp

- 0 to 105°F (-20 to 40°C) hazardous locations integral mount

- ±0.5% of reading repeatability

- 0.3 to 30 seconds adjustable response time

- UltraLink software utility

- Bi-directional flow measurement system

- UL 61010-1 & CSA C22.2 No. 61010-1

- Class I Div. 2 Groups C & D

- T4 to UL 1604 & CSA 22.2 No. 213

Description

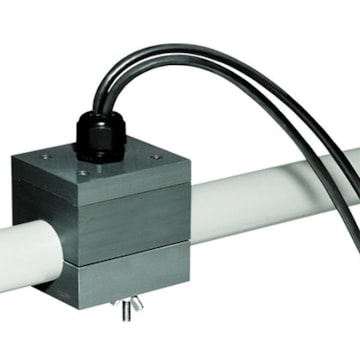

The Dynasonics TFXL ultrasonic flow meter clamps onto the outside of a pipe and does not contact the internal liquid. This non-invasive system allows solids to pass through the pipe with no effect on the flow meter. Y-strainers or filtering devices are not needed. In addition, installation of the Dynasonics TFXL ultrasonic flow meter is easy and low cost.

The Dynasonics TFXL ultrasonic flow meter provides instantaneous rate and accumulated flows along with 4-20mA and pulse outputs. Available with or without a local display, the Dynasonics TFXL ultrasonic flow meter is housed in an enclosure suitable for outdoor mounting. Compact integral mount systems can accommodate pipes 2 inches [50 mm] and smaller. For additional flexibility, remote mount systems are available for pipe sizes 1/2 inch [12 mm] and higher. A software utility is available for customer configuration and in-field calibration.

Greater accuracy can be attained in applications with high levels of entrained gases. The Dynasonics TFXL ultrasonic flow meter will automatically correct displayed flow rates and electronic outputs.

The inherent advantages of the Dynasonics TFXL ultrasonic flow meter over competitive technologies include ease of installation, immunity to suspended solids and gas pockets, and a large bi-directional measuring range. In addition, the non-contact design eliminates any fluid compatibility issues. The Dynasonics TFXL ultrasonic flow meter was designed to replace mechanical flow meters in applications where liquid conditions tend to damage or impede mechanical flow meter operation. No maintenance of the Dynasonics TFXL ultrasonic flow meter is required.

Operating Principle

Transit time flow meters utilize two transducers which function as both ultrasonic transmitters and receivers. The flow meters operate by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers. The burst is first transmitted in the direction of fluid flow and then against fluid flow. Since sound energy in a moving liquid is carried faster when it travels in the direction of fluid flow (downstream) than it does when it travels against fluid flow (upstream), a differential in the times of flight will occur. The sound's time of flight is accurately measured in both directions and the difference in time of flight calculated. The liquid velocity (V) inside the pipe can be related to the difference in time of flight (dt) through the following equation: V = KDdt, where K is a constant and D is the distance between the transducers.

Documents

Spec Sheets

Manuals

Application Notes and White Papers

Links

Other

Accessories

Required Components

These additional components are required for the operation of your product. We strongly advise you to purchase these components unless you already own them or own a suitable alternative.

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Need Help? Call a Flow engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET