Optris CTlaser G5 Infrared Temperature Sensor

Fixed infrared pyrometer measures the temperature of glass surfaces as small as 0.04 inches with temperature ranges from 212 to 2192°F & 5µm spectral range.

Overview

Features

- Temperature ranges

- 212 to 2192°F (G5L)

- 482 to 3002°F (G5H)

- 392 to 3002°F (G5HF)

- Optical resolution

- 45:1 (G5L)

- 70:1 (G5H)

- 45:1 (G5HF)

- Response time

- 120ms (G5L)

- 80ms (G5H)

- 10ms (G5HF)

- 5µm spectral range

- 0.1 to 1.1 emissivity

- Universal analog output

- 160mA max current draw

- 8 to 36VDC power supply

- IP65 NEMA-4 front mountable

- At vacuum processes up to 10–3mbar

What's in the Box

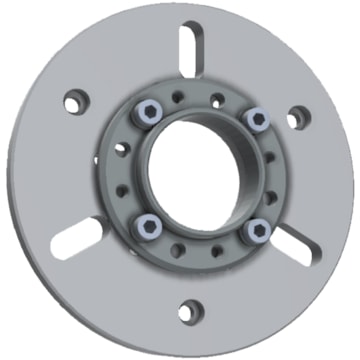

- Mounting nut

- ACCTLFB mounting bracket

- 3m standard head cable

- Electronic box with LCD display

- Programming keys

- Manual

Description

The Optris CTlaser G5 infrared temperature sensor measures glass temperatures from 212 to 2192°F and is well suited for applications in container, vehicle glass, light bulb, and solar cell production. Dual laser aim provides exact marking of measurement areas as small as 0.04 inches from a distance of 2.76 inches.

Selectable analog outputs and multiple digital interfaces offer high variability. The CTlaser G5 features peak hold, valley hold, average, and an extended hold function with threshold and hysteresis, all field configurable with the USB programming kit (ACCTUSBK). Field selectable analog output options include 0/4-20mA, 0-5 and 0-10 V, type K or J thermocouples, and alarm. Optional USB, RS485, RS232 interface, 2 optically isolated relay outputs, CAN-Bus, Profibus DP, and Ethernet available with plug-in options.

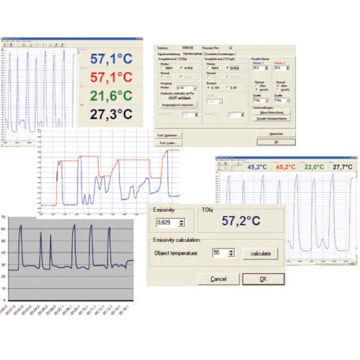

The Optris Compact Connect temperature analysis software is available as a free download and is necessary to document and analyze temperature measurement data. It is compatible with all netbooks, notebooks, and PC systems via Windows XP, Windows Vista, Windows 7 and 8.

Documents

Spec Sheets

Manuals

Other

Links

Accessories

Cables

Software

Accessories

Please consider these optional accessories.

Applications

Here's how some of our customers use this product...

Improving Consistency in Glass Manufacturing With Accurate Temperature Measurement

The Background: Our customer manufactures quartz class tubes for the purpose of ultraviolet disinfection in process water applications. Glass dimensions are specifically tailored to fit the needs of the end customer.

The Problem: The customer has been having problems related to consistency and quality due to issues with maintaining the optimal temperature while working the glass. The process involves a glass cylinder tube inserted into a fixture and heated to a certain temperature. Once the correct temperature is reached, pads are pressed together to form the end seal. If the temperature is not correct, the seal created may need to be reworked manually with a torch, adding a significant amount of time to each piece. The current re-work rate is around 3% which is not efficient.

The Solution: We suggested the Optris CT Laser fix mounted infrared thermometer which has a wavelength that is specifically suited for glass measurement. The 5µm wavelength greatly minimizes reflections and creates consistent readings of the glass surface. Some of the diameters are also fairly small and the powerful optics with dual lasers converge to easily set up the device. Accurate non-contact temperature measurement improves the process and decreases the amount of time reworking the piece.

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open 8:00 am to 5:00 pm ET