Fluke Calibration 6109A High Temperature Calibration Bath

Portable unit with 95 to 482°F temperature range that calibrates 4 sensors at once for less downtime during calibrations.

Overview

Features

- Typical heating time:

- 95 to 212°F in 25 minutes

- 212 to 482°F in 45 minutes

- Typical cooling time:

- 482 to 212°F in 35 minutes

- 212 to 95°F in 55 minutes

- 15 minute settling time (typical)

- 0.1°F display accuracy

- 4:1 test uncertainty ratio

- 115VAC power supply

- 4.3 x 6.1in tank volume

- Traceable NVLAP-accredited calibration included

- Global Fluke support and service included

- 1 year warranty

- covers materials, labor, and calibration

- Meets US FDA & ISO clean room standards

Description

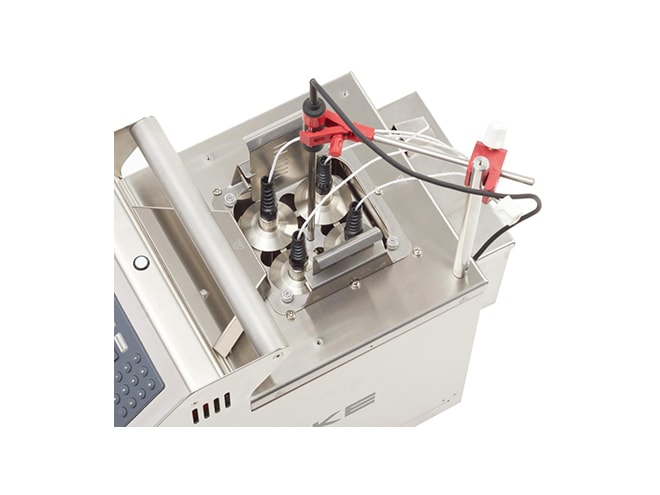

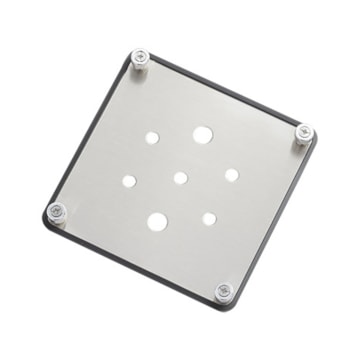

The Fluke Calibration 6109A high temperature calibration bath can calibrate up to four sensors at once in a short amount of time. It's speed and accuracy lessen the downtime that impacts quality and results in product batch loss. The large tank volume is designed to hold odd shaped sensors of varying lengths with extra room for a reference thermometer. It is available with process electronics to connect to an external reference probe.

Each bath features a large color display that indicates date and time, bath fluid temperature, setpoint temperature, control indicator when the fluid is at setpoint, and heating status. The system display accuracy covers all sources of error including calibration uncertainty, stability, uniformity, and repeatability.

An indicator is located on the very top of the bath, providing a 360-degree visual indication when the bath fluid has reached its setpoint temperature and is ready for you to start making measurements. A warning indicator lights up if the fluid temperature reaches above 140°F, alerting the operator that the bath fluid and tank area are hot and should not be touched.

The unit's portability makes it easy to perform calibrations on platforms, crawl spaces, and other hard to reach parts of a plant. It features a fixed, non-rotating bail handle, enabling most people to carry a bath with one hand. Two recessed handles on the bottom of each bath make it easy to move from a shelf to a cart or bench top. A sealed lid protects against fluid spills while moving the bath.

The stainless steel tank and panels are rust resistant, easy to clean, and can withstand harsh sterilizing chemicals. The synthetic materials used for decals, keypads, and feet do not harbor bacteria. The keypad is sealed against moisture ingress to protect against damage during cleaning or in non-controlled environments.

This calibration bath is designed for pharmaceutical, biotechnology, food processing and storage, clean process manufacturing, chemical reactors, steam-in-place process, autoclave sterilization, and calibration of tri-clamp sanitary sensors in clean room environments.

Documents

Accessories

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET