HOBO UX90 Series Data Loggers

Fast reliable measurements of state, pulse, event, runtime, light on/off, motor on/off, occupancy/light.

Overview

Features

- Available in 4 measurement options

- State, event, & pulse

- Light On/Off

- Motor On/Off

- Occupancy

- "Time-of-use" data loggers

- 84k or 346k measurement capacity

- LCD displays Time on or % on

- Auto-calibration & signal strength indicator

- Flexible logger Start and Stop options

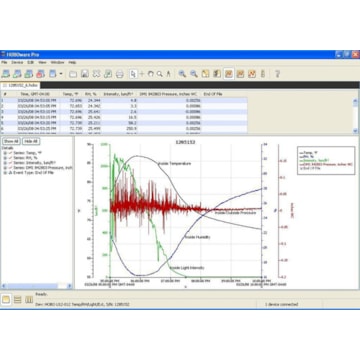

- Compatible with HOBOware & HOBOware Pro software

- For logger setup, graphing and analysis

- Operating temperature range: -4 to 158ºF (-20 to 70ºC)

Description

The HOBO UX90 Series Data Loggers is the industry's lowest-cost, most comprehensive family of "time-of-use" data loggers. The new toolbox suite includes LCD display data loggers for measuring motor on/off status, electronic pulses, state changes, and occupancy and light-use patterns. Use rare-earth magnets, 3M Command Strips, or mounting tabs to affix to a surface reliably.

Leveraging patent-pending technology, HOBO UX90 data loggers streamline energy audits and make field deployment fast and reliable. Accompanying HOBOware software also reduces deployment time. Time-saving features allow HOBO UX90 users to batch-configure and readout hundreds of loggers in a fraction of the time. Additionally, the software features a Bulk Export Tool that allows users to export data files to text format for use in spreadsheets and other programs.

Documents

Spec Sheets

- HOBO UX90-001 Series Data Loggers Datasheet PDF (76 KB)

- HOBO UX90-002 Series Data Loggers Datasheet PDF (76 KB)

- HOBO UX90-004 Series Data Loggers Datasheet PDF (72 KB)

- HOBO UX90-005 Series Data Loggers Datasheet PDF (76 KB)

- HOBO UX90-006 Series Data Loggers Datasheet PDF (76 KB)

Manuals

- HOBO UX90-001 Series Data Loggers Manual PDF (474 KB)

- HOBO UX90-002 Series Data Loggers Manual PDF (495 KB)

- HOBO UX90-004 Series Data Loggers Manual PDF (475 KB)

- HOBO UX90-005 / UX90-006 Series Data Loggers Manual PDF (721 KB)

Software

Links

Accessories

Required Components

These additional components are required for the operation of your product. We strongly advise you to purchase these components unless you already own them or own a suitable alternative.

Cables

Software

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Monitoring Motor Run Time

The Background: Our customer is a municipal swimming pool that needs to run the pump a specified amount of time each day. They require a method to monitor the motor run time of the pump to ensure they are meeting the time requirement.

The Problem: The pump has no additional contacts to provide input to a data logger to monitor the state of the motor.

The Solution: We recommended the HOBO UX90-004 which includes a built-in motor on/off sensor that detects the electromagnetic field of a motor as its running. By simply placing the UX90-004 in the vicinity of the pump motor it will recognize when the motor is running and log accordingly. This is a quick and easy way to monitor motor run time without the need to add contacts or additional wiring.

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET