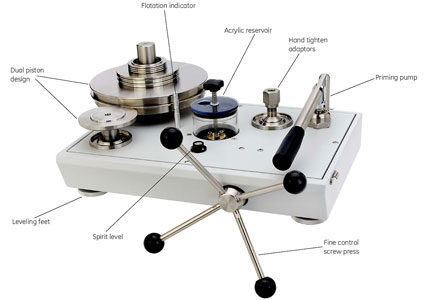

Fluke Calibration P3000 Hydraulic Deadweight Testers

Hydraulic deadweight tester, ranging up to 20,000 psi, accuracy better than 0.015% of reading.

Overview

Features

- Pressure ranges to 20,000 psi (1400 bar)

- Accuracy better than 0.015% of reading

- Increased accuracy option of 0.008% when PressCal software is purchased

- Mineral oil and distilled water models

- Dual piston models allow calibration over a wide range

- Psi, bar, kgf/cm2, kPa and MPa ranges available

- Built-in lever style hand pump now standard on all hydraulic models

- Mounted spirit level and adjustable feet

- High-quality screw press for fine pressure control

- Test Station design with O-rings eliminates the need for PTFE tape or wrenches

- Acrylic reservoir provides visibility of fluid level and quality

- Improved case with spring loaded latches for hood

- Built-in drain plug to remove old fluid

- Sturdy weight box with hinged lid and side handles for easy transport

Description

The Fluke Calibration P3000 Hydraulic Deadweight Tester (formerly Pressurements) is the culmination of over 50 years experience in the production and design of primary pressure standards. With features designed to improve accuracy and performance, increase reliability, and simplify operation, the P3000 can be used to calibrate virtually any pressure sensing device, including transducers, transmitters, gauges, or pressure switches.

Each P3000 tester is supplied with a detachable lid which makes it neat, compact, and easily portable. The weight masses are stored in a high-quality case with a self-locking mechanism to protect them during transit. All P3000 testers are provided with a traceable certificate of accuracy, weight mass details, 1/8, 1/4, 3/8 and 1/2 NPT or BSP female adaptors, operating fluid (where applicable), and spare seals.

Operating Principle

Deadweight testers are the primary standard for pressure measurement. Utilizing the well proven piston-gauge system consisting of a vertically mounted, precision lapped piston and cylinder assembly, accurately calibrated weight masses (Force) are loaded on the piston (Area), which rises freely within its cylinder. These weights balance the upward force created by the pressure within the system. The pressure is measured when placed on a correctly spinning and floating piston. The total pressure measured is the summation of the weights plus the piston weight carrier assembly.

Instrument Base

There are three basic variations of hydraulic deadweight tester: single low pressure, single high pressure, and dual piston models. Pressure is generated and controlled by means of a high quality screw press located on the front of the tester. A built-in hand pump is included as standard for all hydraulic models to prime the system and accommodate large volume requirements.

Piston/Cylinder Assemblies

The piston/cylinder assembly is the heart of each deadweight tester. They are manufactured from materials that provide stability, durability, and low thermal coefficients and distortion.

Weight Masses

Standard weight masses are series 3 non-magnetic austenitic stainless steel. Each mass is marked with the serial number of the instrument and the nominal pressure value relative to the high- or low-pressure piston, when applicable. Optional fractional weights are stainless steel and/or solution heat treated aluminum.

Documents

Accessories

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open 8:00 am to 5:30 pm ET