Trace Moisture for Industrial Applications

Water is an essential resource for most forms of life and is abundant on our planet. However for most industrial applications, water is considered a contaminant, and a tremendous amount of effort, engineering, and money is spent trying to remove it.

The basic goal of any humidity measurement is to determine the amount of water vapor, i.e. gas, in a certain media or process. Humidity measurements can cover a broad dynamic range starting from 1 part per billion up to completely saturated steam, which is an impressive dynamic range of 10 to the power of nine [1]. Trace moisture refers to the measurement of small amounts of water vapor, usually in the parts-per-million range.

The most common application for trace moisture measurement is Compressed Air. Compressed air is often referred to as the fourth utility, it can be used for power tools, paint booths, heavy machinery operations, etc. When too much water is present in a compressed air line, several problems can occur, such as corrosion, icing, and damage to equipment down the line.

Trace moisture measurement is also essential for applications dealing with Nitrogen or other high purity gases. Hydrogen-Cooled generators must have a very dry gas to prevent any potential sparks and explosions. [2], Power transformers need a pressurized nitrogen blanket on top of the insulating oil. All these applications require careful and precise measurement of the water content.

Using Aluminum Oxide Sensors for Trace Moisture

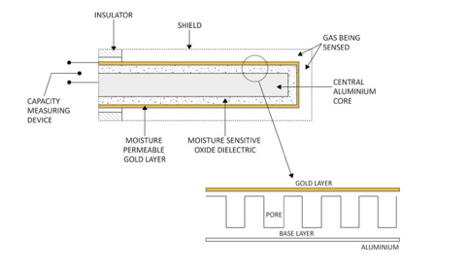

There are several methods to measure trace moisture. Aluminum Oxide sensors are considered the workhorse of the industry, they are relatively simple to manufacture and cover a wide range of measurements, ranging from -100 to +20 ºC dewpoint. Aluminum Oxide sensors have a thin gold film deposited on top of a porous Aluminum Oxide layer, that adsorbs water vapor within it. The central aluminum core and the gold film form a 2-place capacitor, where the dielectric is the oxide layer, and the water absorbed by it is directly related to the moisture content of the gas surrounding the sensor.

Although Aluminum Oxide sensors are very versatile, they are not perfect. Some of its downsides include drying time and accuracy. If a sensor’s oxide film is fully saturated with water and is introduced in a process with clean, dry air, it may take a significant amount of time, up to several hours, for this water to “dry” and the sensor to accurately register the true dew point of the process. Drying time is dependent on several factors such as flow rate and line pressure.

With an accuracy of around ±1 ºC to 2 ºC, Aluminum Oxide sensors are typically not used for high-accuracy applications. Whenever a higher degree of accuracy is required, it is recommended to use different technology, such as Chilled Mirror Hygrometers.

Using Chilled Mirror Hygrometers for Trace Moisture

While Aluminum Oxide sensors rely on the indirect measurement of dewpoint by correlating its capacitance with dew point, Chilled Mirror Hygrometers (CMH) measure dew points directly. Using a reflective surface, CMHs cool this surface down to the exact temperature at which dew starts to form and use a light source to detect it. By controlling the temperature of this mirror-like surface, it is possible to determine the exact dewpoint temperature of the gas under test. This method results in an impressive accuracy, around ± 0.1 ºC or better, making this the most accurate way of measuring trace moisture.

Chilled Mirror Hygrometers need a clean gas sample, low pressure, and several other requirements. Most applications consist of laboratories and R&D companies. A newly developed technology is the Tunable Diode Laser Absorption Spectroscopy (TDLAS), which provides a drift-free way to measure trace moisture with virtually no drying time.

Many methods exist for measuring trace moisture. No single method is perfect and the best one will depend on the application. New technologies are constantly being developed, each one with its own benefits and downsides.

Still Need Help? Call an Engineer Today

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.

Sources: [1] (3) Wiederhold, P. R. Water Vapor Measurement; Marcel Dekker: New York, 1997 [2] GE Industrial Sensing, www.gesensing.com, Hydrogen Purity in Hydrogen-Cooled Generators, 2005