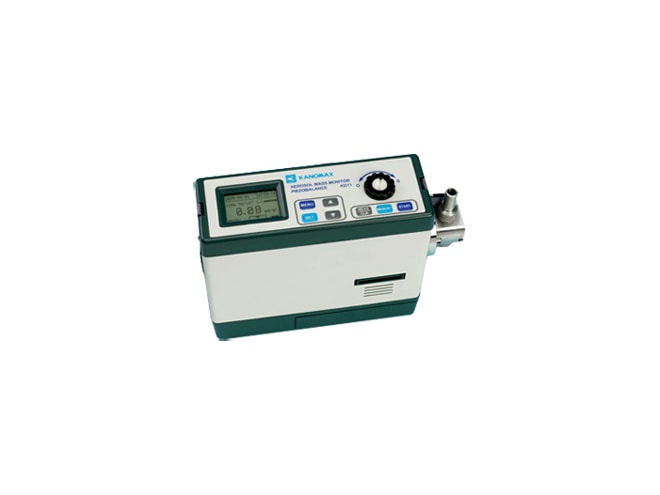

Kanomax 3521 & 3522 Dust Monitors

Piezobalance technology for real-time measurements of dust concentration.

Overview

Features

- Measuring Range: 0.02-10mg/m3

- Sampling Flow Rate: 1liter/min

- Accuracy: ±10% of reading ±1 digit (0 to 5 mg/m3); ±20% of reading ±1 digit (5 to 10 mg/m3)

- Measuring Time: 24 sec or 120 sec (preset); 10 sec to 3600 sec (manual)

- Data logging: Max 500 date and time stamped samples

- Digital Output: RS232C

- Piezobalance technology “weighs” mass concentration of particulates

- Data can be reviewed on-screen, printed or downloaded to a computer

- Software included for easy data download and processing

- Easy operation requires no special training

- Simple cleaning mechanism for easy maintenance

What's in the Box

- Data processing software

- RS232C cable

- Impactors

- Cleaning kit

- Ni-MH battery pack

- AC adapter

- Carrying case

- Calibration certificate

Description

The Kanomax 3521 & 3522 dust monitors utilize piezobalance technology for real-time measurements of dust concentration. Featuring easy set up and operation, the 3521 and 3522 are perfect choices for a wide range of applications including IAQ investigations, industrial hygiene, occupational health & safety, product quality control, and laboratory research.

The Kanomax 3521 is equipped with 4 and 10µm impactors while the 3522 is equipped with a 2.5µm impactor. Unlike conventional dust meters which count particles, piezobalance dust meter like the 3521 and 3522 "weighs" mass concentration of particulates. As an air sample enters the system, it travels through the impactor, which captures and removes larger particulates away from the sample. Smaller particulates become electrically charged and deposited on the piezo-crystal. The total mass of the deposited particulates affects the piezo-crystal's frequency. Since the change in frequency is proportional to the mass of the particulates, the actual weight of the particulates is obtained.

The Kanomax 3521 and 3522 have measuring ranges of 0.02-10mg/m3 with an accuracy of ±10% of reading ±1 digit (0 to 5 mg/m3) or ±20% of reading ±1 digit (5 to 10 mg/m3). The sampling flow rate is one liter/min. Data can be reviewed on-screen via a backlit display that is easy to read in poor lighting conditions. Data can also be transferred to a computer via an RS232C port. An optional printer is available for creating immediate record of test results. The meters can data log up to 500 readings. The included software makes it easy to download and process data.

The Kanomax 3521 & 3522 dust monitors are easy to operate and require no specialized training. Cleaning, which is required after every 10-20 measurements, is made simple by a cleaning mechanism which greatly simplifies maintenance.

Documents

Spec Sheets

Other

Application Notes and White Papers

Links

Accessories

Cables

Power Supplies

Printers

Batteries/Chargers

Cases

Accessories

Please consider these optional accessories.

Applications

This product can be used in the following applications:

Here's how some of our customers use this product...

Monitoring Oil Mist in a Machine Shop

The Background: Our customer is a manufacturing facility that has an in-house machine shop. In order to prevent the overheating of machine tools and to trap fine metal particles, a cutting fluid is used. The customer needs a reliable way to ensure that this cutting fluid is not posing a health risk to the machinists.

The Problem: Fine droplets of the cutting fluid can become suspended in the surrounding air creating an aerosol which poses a long-term health risk to workers who breathe it in. Measuring the concentration of this aerosol is difficult with standard light scattering particle measurement methods. NIOSH 5524 outlines approved testing methods, many of which require reagents and complex sample systems. Some companies rely on third-parties for testing requiring them to pull a sample and send it out to a lab to get the concentration level. The results may not be available for a week or more.

The Solution: We recommended Kanomax 3521 dust monitor which uses piezobalance technology to accurately measure the mass per volume in real time. This is a highly effective way to monitor oil mist concentration. The information is available immediately and any necessary adjustments for filters or worker protective equipment can be implemented.

Need Help? Call a Temperature engineer at 1-800-884-4967

We're open Mo-Th 8am to 5:30pm. Fr 8am to 5pm ET